wye delta starter inrush current

Wye Delta Advantages Inexpensive Starting Torque is reduced to 33 6 lead motor requiredProduce High torque per amp of Line current No heat is produced or tap changing of transformers increases efficiency Wye Delta Disadvantages Starting torque is reduced to 33 and cannot be adjusted. Wye-delta motor starting reduces the inrush current to one- third of the delta value or approximately 200 of the motors full-load current when the motor is started in wye.

Electronic Soft Starting Of Large Marine Motors Dieselship Uk

But using a star delta starter does not provide a.

. In delta connected devices line current is equal to winding current multiplied by the square root of 3 or 1732. Delta Configuration 435 amps x 3 754 amps Æ 307 lbs-ft. For simplicity lets assume we have a 3 phase single voltage motor with each phase wound for 480 volts.

Delta run current is about 86A. Bottom line this is a cheap way of making a Wye-Delta starter. Some wye-delta starters for large motors can cause peak currents in the power system to exceed the normal trip settings of branch circuit breakers.

It helps to reduce the inrush current when the motor starts. A wye-delta starter requires the motor to be internally connected in the peckerhead so that ___ conductors are extended to the starter enclosure. Wye Delta 10 Solid State 12 Comparing the Reduced Voltage Starters 13.

Ive adjusted the time from approximately 25 seconds factory setting to. Current inrush from starting up the large motors can result in anything from flickering. Referring to the example used earlier for a 15 kW20 Hp motor the wye connection current would be 6051 A at 400480V and 33 of the full load torque at starting.

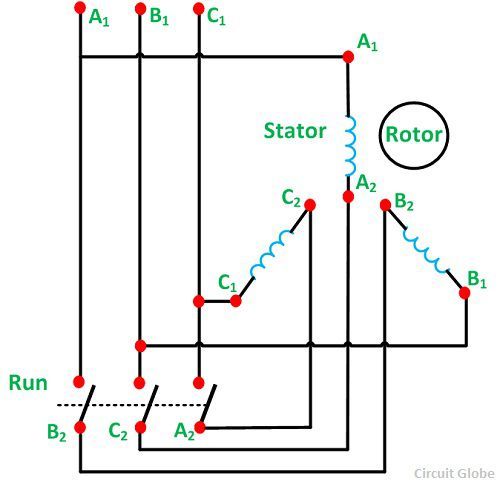

Thess theory of inrush current c. When starting in star Y wye the current is 13 thus 7A and the starting current assumed also 600 will be 42A. 4 Wye Delta-Wye Delta starting requires the motor have connection point to each of the three coil windings.

The phase-to-phase current in a Delta circuit is only 1732 times the phase current but it is two times the phase current in a Wye circuit. Various methods are followed to start induction motors out of which star-delta starters are the most commonly used ones to reduce the starting current. Reduce the starting current and reduce the starting torque.

The timer was one of my thoughts as well. Induction motors are robust and reliable and are used in all industries across the globe. Are best suited for applications where low starting torque and minimal line current are required.

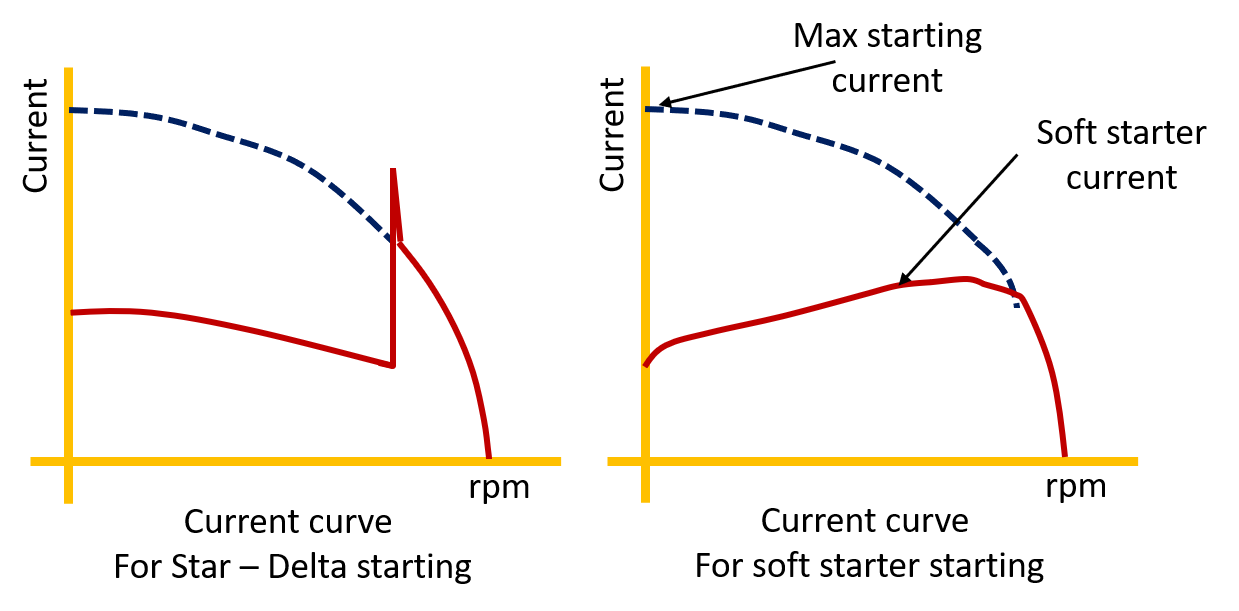

In the transition from Wye to Delta there can be a HUGE current spike if the voltage is leading the current when it happens and that is likely causing the non-adjustable magnetic trips on that device to take it off-line. The received starting current is about 30 of the starting current during direct online start and the starting torque is reduced to about 25 of the torque available at a DOL start. The electromechanical starter connected in the wye configuration draws 13 the line current which results in 33 of the starting torque.

The star-delta method is usually only applied to low to medium voltage and light starting Torque motors. The surge in current can cause a lot of problems as the electrical system will be hit with a massive demand at once. For applications where across-the-line or wye-delta starting would be appropriate.

Cable sizing is normally adequate to meet the demands of the Delta configuration start. Remember that while the Delta starting current is higher the. A motor that is to be started in wye and run in delta must have at least ___ leads.

Both types are diagrammed in accompanying illustrations. So if current in one of the delta connected motor windings is 100 amps then line current will be 1732 amps. After receiving a start signal our model MCO controller energizes the first run contactor and the wye contactor to connect the motor to the line in wye.

Closed transition starters do not permit this peak to occur. Star-delta starter Wye-Delta Starters Circuit working. Wye-Delta Open Single Source Inrush Current.

This is specially wound with six leads for delta and Wye connections. When converting a Wye-Delta system to an RVSS the cables from the RVSS to the motor are doubled paralleled as the motor is at least a six-lead motor. Answer 1 of 5.

Low Starting Torque. In Wye connected devices line current is equal to winding current. Ad Shop compact basic full featured AC motor soft starters from AutomationDirect.

Star-Delta starter design tool Wye-Delta starter design tool. The star-delta wye-delta starting method controls whether the lead connections from the motor are configured in a star or delta electrical connection. Transition starting although.

Part Winding Soft Starting. A large induction motor in delta can produce an inrush current of over 5 times its full load capacity when starting up. Star-delta starters are widely used for starting three-phase induction motors.

Here is an advanced Star-Delta starter design tool that will help you select the optimum current rating of contactors fuses and circuit breakers MCB MCCB. If you want to get into the math of it all read this link. This is why the constant of 1732 appears in the equations used to calculate wattage and other values in three-phase circuits.

200 Motor Starting Operation. Wye Delta Closed. A lead from each end of each phase is brought out of the stator winding and into the motor connection box in the field commonly referred as the PH.

This type of starter can supply more current to the motor than other reduced. We use star delta starters to reduce the current when a motor starts. Since under normal start delta the breaker shall withstand the starting process select 60A for a short-time start with 126A in.

The initial inrush current is about 280A. Once it gets up to speed on star it draws about 56A. Motor start theory d.

It is the so-called open transition wye-delta starter thats the culprit. Transition starters are available at an extra cost. Star-delta starters are cheaper than soft-starters and are widely seen in.

A star-delta starter wye-delta motor starter is a way of starting an induction motor by using 3 contactors 1 overload relay and 1 timer relay. The initial connection should be in the star pattern that results in a reduction of the line voltage by a factor of 13 577 to the motor and the current is reduced to 13 of the current at full. The basic wye-delta starter configuration is designed for.

Wye-Delta Open Variable Speed. Most dual voltage motors are compatible with the part winding starter at 230 volts. It can reduce current inrush to 13 of direct-on-line starting current.

This starting method only works when the application is light loaded during the start.

Motor Star Delta Starter Working Principle Instrumentationtools

Automatic Starters For Star Delta Motors

Star Delta Starter Wye Delta Starters Circuit Working

Star Delta Starter Wye Delta Starters Circuit Working

Star Delta Motor Starter Explained In Details Eep

What Is Star Delta Starter Theory And Method For Star Delta Starter Circuit Globe

Figure 1 From Research On A Novel Wye Delta Soft Start Method Of Three Phase Induction Motor Semantic Scholar

Traditional Star Delta Motor Starting Method Used In Practice Eep

Star Delta Starter Explained In Plain English Electrical4u

Soft Starter Vs Star Delta Starter Full Comparison

Why Is Star Delta Starter Preferred With An Induction Motor Quora

Comparision Of Dol And Star Delta Motor Starting

Why Wye Delta Starters Cause Breakers To Trip

Starting Current Waveform With Star Delta Starter Download Scientific Diagram

Three Phase Start Delta Motor Starter At Higher Ampere In Delta Configuration Electrical Engineering Stack Exchange

Star Delta Starter Design Tool Wye Delta Starter Design Tool